Blacksmithing & Toolmaking

Drill Bits: Historic Holemakers

Course Overview

Drill bits are a fascinating and diverse set of tools that were added to our tool box alongside the stone hammer and crude chisel. While the latter haven’t changed much, drill bits and even the drills themselves have never stopped evolving. In this class we will explore the historical significance and development of the bit and some of the many tools that power them including the pivot, dee, spade, and spoon bits and bow and pump drills, braces, and even the egg beater!

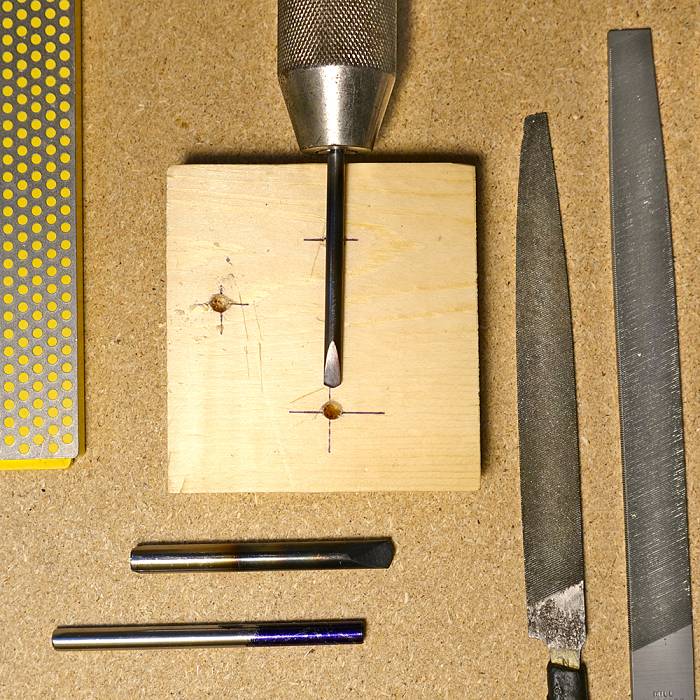

On our first day, students will be introduced to the geometry of the cutting surfaces and work from blueprints to make their own pivot drill bits in various sizes from readily available O1 drill rod. We will start with the traditional technique of cutting the bits with hand files and stones and then incorporate more modern tools like grinding wheels, abrasive belts, and jigs. We will use a propane forge to harden our drill bits and temper using a torch.

On day 2, we will practice one traditional case hardening method using a Roman recipe of organic charcoal to carburize mild steel. Each student will have the opportunity to perform each step from making the charcoal to firing the steel in a propane forge. Because this is a slow process, students will perform the final step with pre-prepared steel.

On day 3, students will have time to make more drill bits or start an optional project, which includes forging more advanced bits, like spades or spoon bits, or constructing a simple pump drill from a kit. Students who plan to leave early can take a project with them.

Physical Ability/Skills Needed

- Able to stand for a few hours each day

- Dexterity to use a hand file and power tools

Required Tools

- Closed-toe shoes

- Cotton or wool clothing

Optional Tools

- Files: full-sized metal working files and needle files

- Sharpening stones or diamonds

- Layout tools: protractors, calipers, and permanent markers

- Personal protective equipment: safety glasses and/or face shield, earplugs, respirator

- Hand lotion